Managing the maintenance process

Lanas Trinidad is Uruguay’s leading producer and exporter of washed and combed wool, with a history rooted in the wool industry since 1916. The company exports to some of the world’s most demanding markets and operates with a strong commitment to the circular economy. By prioritizing efficiency and environmental care, Lanas Trinidad supports producers with tools for animal welfare, superior genetics, and sustainable practices such as green tap conditioning and recyclable packaging.

The Challenge

Lanas Trinidad required an industrial maintenance system to enhance process efficiency and minimize equipment downtime. The manual management of maintenance tasks was error-prone and caused delays in identifying and addressing issues. The challenge was to develop a system capable of automating maintenance management in real time.

The Solution

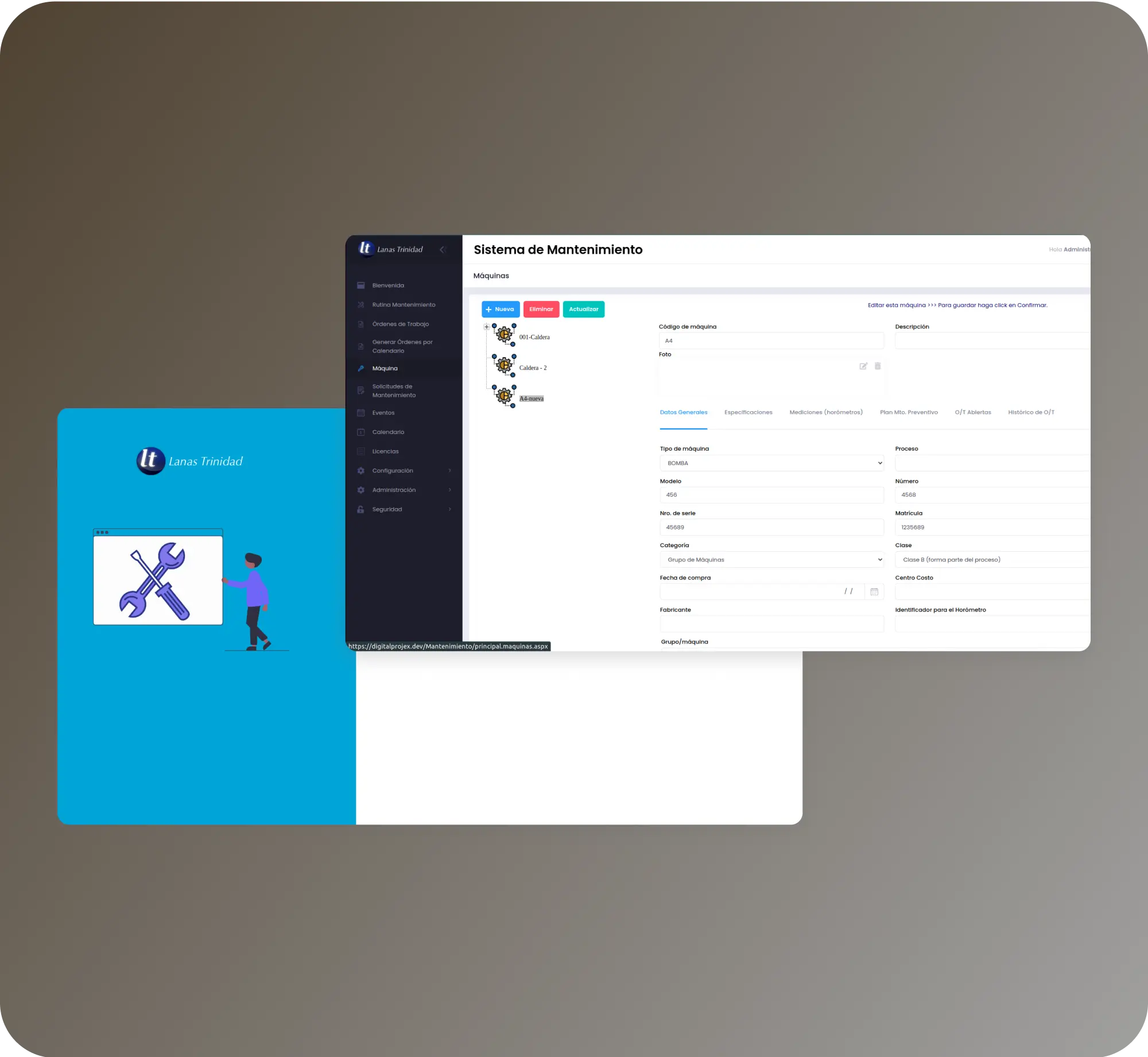

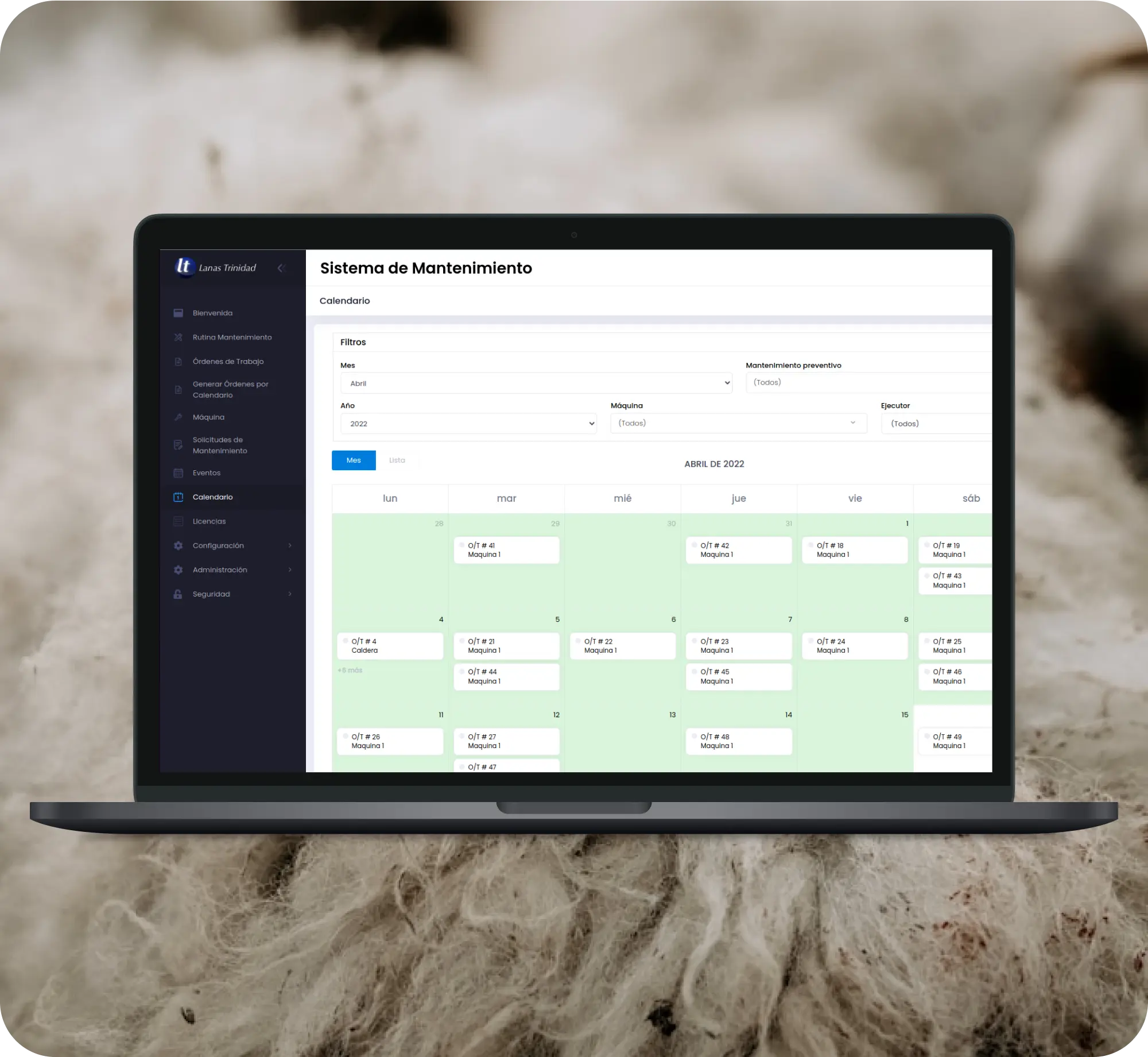

DigitalProjex designed and implemented a customized web-based system for Lanas Trinidad. This solution offers centralized and real-time access to maintenance information through an intuitive interface. Key functionalities include:

Registration, monitoring, and scheduling of equipment maintenance.

Cataloging of company equipment with detailed technical specifications.

Management of maintenance work orders, from assignment to closure.

Processing of spare parts inventory.

Generation of statistical reports to aid strategic decision-making.

The Result

The implementation of the industrial maintenance system significantly improved Lanas Trinidad’s operational efficiency by reducing machinery downtime and enhancing the accuracy of maintenance information. These improvements have enabled the company to make precise decisions regarding preventive and corrective maintenance. Overall, the system has resulted in considerable time and resource savings, boosting productivity and performance across the organization.